.

Disclaimer: This post is about the John Deere 4010, not the 4020. I may use phrases like “game-changer” and “ground-breaking” and some of the 4020 nerds aren’t going to be happy about it. Still, the fact remains…without the 4010, there is no 4020. (And I say “4020 nerds” lovingly…bless their hearts.)

So, now that the 4020 guys have all stomped off to the barn to sharpen their pitchforks and light their torches, we’ve got a few minutes to talk about how John Deere changed the game in 1960 with the New Generation of Power.

And how it all got started in April of 1953.

In an old meat market.

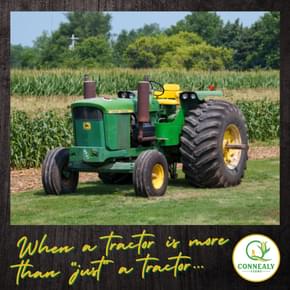

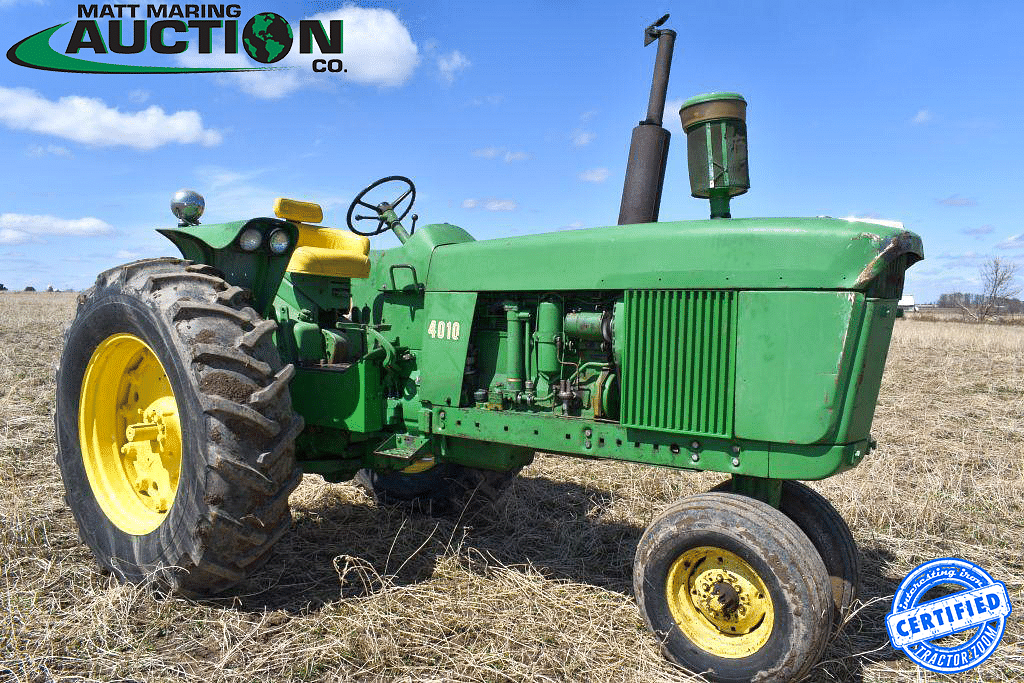

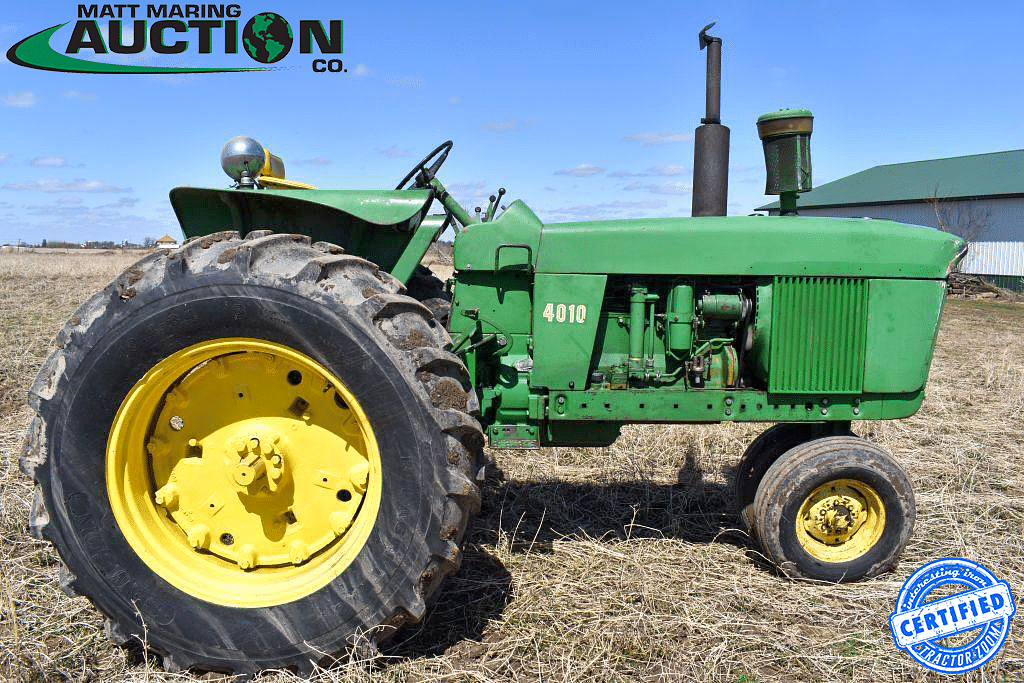

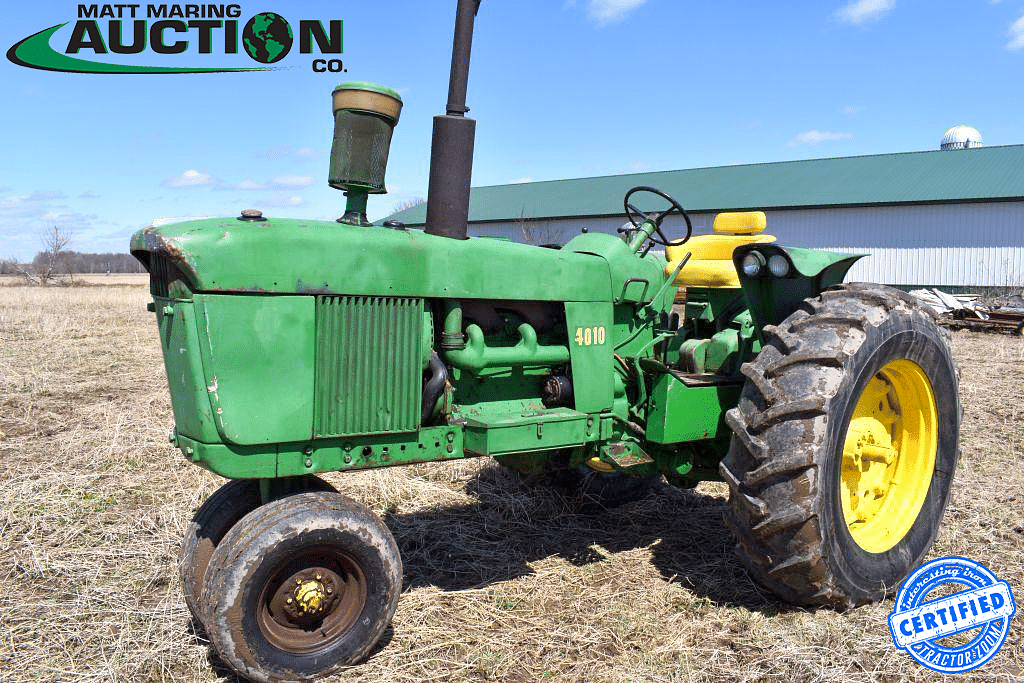

Before we go there, though, here’s the details on the John Deere 4010 in that picture up above.

Auction Date: June 16, 2022 – 10AM CDT (Online bidding is open right now.)

Auctioneer: Matt Maring Auction Co.

Format: Onsite with online bidding – 10AM CDT start time on the auction!

Location: Boyd, WI

Auction Catalog

Link to the 1961 John Deere 4010

Now, let’s dig in and talk New Gens!

The 2-cylinder is dead…sort of.

So it’s the early 50s. For close to 30 years now, you could have whatever engine you wanted in your John Deere tractor…so long as it only had two cylinders. Most every other tractor company was using a 4-cylinder design at the time (Oliver was mainly using a six-cylinder), and Deere’s management team knew that it wasn’t making up ground as fast as they wanted to.

See, Sales & Marketing (and I suspect a good number of dealers) claimed that the two-banger was outdated, and that farmers didn’t want them anymore. Engineering said that they couldn’t do much more with them without going bigger. That also meant making a wider tractor that wouldn’t work with row spacing. Furthermore, the bean counters said that the machines in the factory weren’t able to keep up with the demand anyway, and that they were pretty inefficient. (And given that some of those machines were going on three decades old, that doesn’t surprise me.)

It was a rare moment in Deere’s history where nearly every department of the company were in complete agreement.

The two-cylinder was dead. If they were to “pass International Harvester” (the famous edict that came from Bill Hewitt in 1955), something had to change.

And in 1953, it did…

The Meat Market

At some point in late 1952 or early 1953, Deere’s management team made the decision to move off of the two-cylinder architecture. Normally there’s some sort of historical documentation for when decisions like this were made, but for the New Gen tractors, the official decision to start work was not. (You’ll start to see a pattern emerging here – and it all revolves around secrecy.) The management team knew that they could use the element of surprise to their advantage, and during the course of the project, they did everything they could to protect that.

Deere’s biggest concern with the project was making sure that NOBODY knew the tractors were coming. People talk, and word gets around. Furthermore, I’m pretty certain that every tractor company out there had spies in Waterloo. People who paid attention when a truck left the factory with something different on the back. People who found ways to cozy up with Deere’s engineers and/or management, listening for hints at what was being built. If it all sounds very cloak and dagger…that’s because it was.

Furthermore, Deere knew how this game was played, because they played it too.

So how’d they keep the John Deere 4010 under wraps?

They rented an old butcher shop in a residential part of Waterloo for a design team to work in! And the first thing they did when they got the keys to the place? They blacked out the windows so nobody could see in. The nosey neighbors in the area feared that somebody was about to open a bar, and they even went to far as to circulate a petition against it! They called it “The Meat Market”, and for about 2(ish) years, that’s where a design team of about 20 engineers and a few outside consultants worked to design the new lineup! In 1955, the company bought land on the outskirts of town and built what later became known as the Product Engineering Center. (Lee Klancher, John Deere Evolution)

Here’s the neat part about The Meat Market…the building is still standing today at the corner of Falls Avenue & Knoll Avenue in Waterloo.

Yep, some of the most game-changing John Deere tractors in history were designed in a building that’s now a daycare!

(Side note: Deere history buffs, let’s please be respectful of the business that currently occupies the space. Thank you.)

Anyway, on with the story.

Design goals: It needs to be green with yellow wheels.

No, this wasn’t the only goal. However, it’s the one that everybody seems to remember, most likely because Charles Wiman (CEO of Deere at the time) made that comment. I believe that it was somewhat tongue-in-cheek, but the fact is, the project goals were a radical departure from what the factory was turning out at the time. It was truly a clean-sheet design.

Here were the goals, from William Purcell’s notes (Purcell, 1961) as laid out in Merle L. Miller’s book, Designing the New Generation John Deere Tractors.

- The styling should not dictate the design of the tractor. The styling should be functional.

- The tractor should be green with yellow wheels (a long-time precedent).

- It should be a “clean design” – not having components projecting beyond the basic sheet metal.

- The rear of the tractor should be simplified in appearance.

- A better location (than over the engine as on the then-current John Deere and competitive tractors) for the LP gas (or fuel) tank.

- The tractor should be more compact for its power.

- The underside of the tractor should be uncluttered, with the frame along the side of the engine.

From a technical standpoint, the goals were fairly routine: state of the art, more power, easier to use, and operator comfort. Miller’s book takes a very deep dive into all of this, so if you want to nerd out on the details, that’s a great place to start!

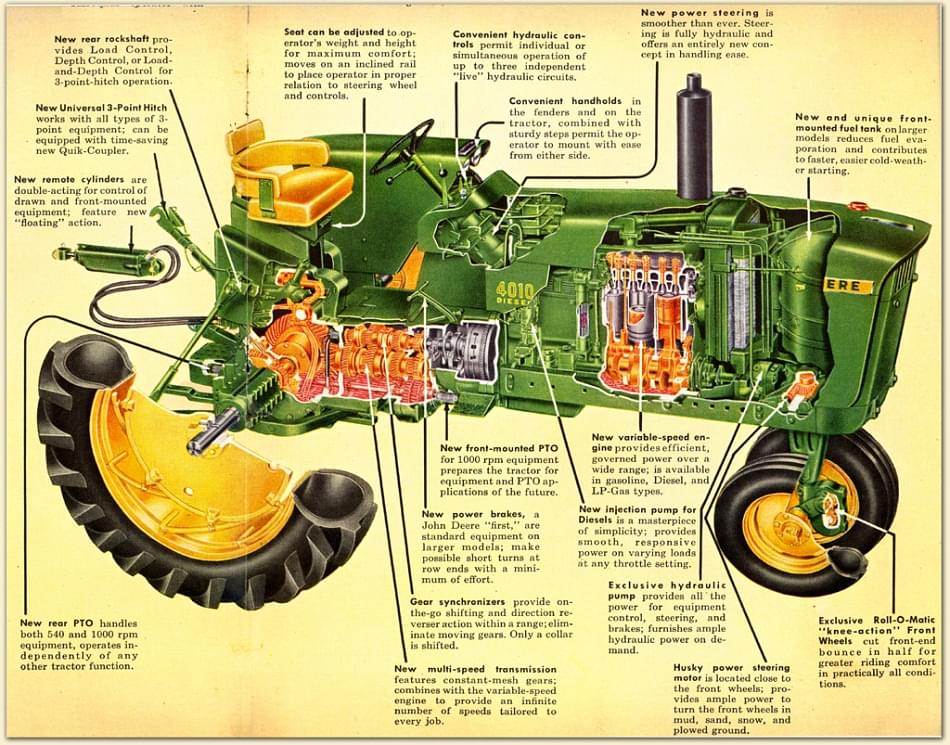

Engines:

Engine development definitely took center stage for the John Deere 4010 (and the rest of the tractors in the series). Multiple different engines were designed and tested – I believe there were five different styles considered. They tested everything from a big two-cylinder to various sizes of inline-four and inline-six – even a couple of different iterations of V-4 and V-6s! In the end, though, the engineers settled on an inline six cylinder; it provided the best power and torque curve with the least amount of vibration. Truthfully, for a row crop tractor, I still think that’s the best configuration. Six in a row makes good power and lots of grunt down low, which is what’s needed when pulling implements.

There were three versions – a 380 cubic inch diesel, a 302 cubic inch gas, and a 302 cubic inch propane. Diesel was the king when the John Deere 4010 went on sale, outpacing the gas and propane by about 10:1. And, as you’d expect, the diesel made the most PTO horsepower (the Nebraska Lab tested it at 84), followed by the gasser (80.86) and trailed by the propane (80.6).

Sheet metal & ergonomics:

Although the goal was function over form with the New Gen series, the designers still wanted something that looked good to the eye. They wanted ultra clean lines that flowed nicely together, so the tractor looked “right” from just about any angle. That’s not a super-easy thing to do, but with Henry Dreyfuss & Associates (HDA) steering the sheet metal, they definitely hit a home run (in my opinion, at any rate). One thing I’ve always loved about these tractors is the way that the joints and body panels line up, and that you don’t see a bunch of fasteners all the way down the hood. Everything is hidden, and to me, that’s ultra-clean design.

From the creature comfort side, the 4010 boasted a number of improvements. The platform became more clearly-defined, and moved forward about a foot. This meant that the seat was now ahead of the rear axle, which resulted in a much more comfortable driving position. It made it easier to see, too. The overall wheelbase was about 6″ longer than a 730, but that made a pretty big difference in the field. Furthermore, the controls moved up onto a dashboard; no more bending over or reaching forward to change gears, etc. Lastly, John Deere and HDA spent a lot of time working on the seat itself, building a suspended, fully adjustable seat for both height and weight. And, with the help of Dr. Janet Travell (who later became well-known for treating President Kennedy’s back problems), they engineered more supportive seat cushions!

Other innovations:

You could do a longer piece on all of the technical innovations on the John Deere 4010 (there’s a lot of meat on that bone), but if I did, this article would take forever to read and people would end up getting pretty bored. So, suffice it to say this; Deere put a LOT of thought and effort into making the New Generation tractors as good – and cutting edge – as they could. Better hydraulics, proper power steering, a more accessible fuel tank, and the 8-speed synchro transmission were all part of the package – and they set a very high standard. Heck, the Mexico-made 4455s had an 8-speed synchro, and they were built into the early 90s!

John Deere 4010: Testing

I believe that the New Generation tractors were tested harder and more thoroughly than anything John Deere had ever built before. No, I can’t prove it, but that’s my perspective. I think the numbers would support it, too. According to a display at Deere’s Tractor & Engine Museum in Waterloo, there were a half million hours logged during the testing process for these tractors.

A half million hours.

Let that sink in for a second.

If you do the math on that, it works out to 57 YEARS.

Now, that sounds pretty impressive (and it definitely is), but let’s also remember that this was spread across 41 test mules, 53 test engines, and all of the new parts that went into them.

Deere was extremely comprehensive when testing these tractors. EVERYTHING had to prove itself before it was approved. The engineers tested stuff that you’d never even think of testing, either, like how hard you could mash a lever before it bent, or how long it took for the seat springs to fall apart. They tested in all climates, on a multitude of different farms from all over the country, and with a multitude of different variables (operator skill level, etc.). To put it real bluntly…John Deere beat on these tractors like rented mules. (And it paid off, too!)

Here’s the most mind-blowing part of all of this, though. Somehow, even through all of this testing out in the open on farms across America, they managed to keep it a secret! From 1956 when Deere began testing out in the open all the way through 1960, they’re pretty certain that none of the competition knew it was happening!

How’d they do it?

They put more emphasis on security than they ever had before. Tractors left the lab in closed trailers that were locked by Deere employees and opened by Deere employees. The truckers didn’t have keys, from what I’ve been told. In some cases, I believe drivers got to the town where the test site was located and surrendered their truck for a couple of hours while Deere’s engineers took it to the actual farm ground and unloaded it. Like I said earlier, it was real cloak and dagger stuff.

Test mules were carefully disguised, too. From a distance, John Deere 4010s look enough like late model Massey Harris tractors that if you painted them red and yellow, nobody could really tell. Obviously today, it’s not hard to tell them apart, but remember…back then, the New Gen tractors were a completely different body shape from anything Deere had ever built. Everybody expected boxy tractors that made two-banger noises, so they didn’t really know they were looking at! It was a brilliant move, honestly, using the casual observer’s mind against them, and the company exploited it very well.

Furthermore, Deere continued to espouse the two-cylinder line, making tweaks here and there all through the fifties. Everybody knew that Deere was sticking with what worked, and that was just the way they were, so it wasn’t out of the ordinary to see the 70 take a new paint job and some subtle changes and suddenly become the 720, y’know?

Deere did a really, REALLY good job keeping the whole project quiet. From the top all the way down, if you weren’t essential to the the new line, you were left in the dark.

Right up until August 30, 1960, that is…

Deere Day – Dallas, TX – August 30, 1960

To launch the New Generation of Power, John Deere pulled out all the stops. They spent 15 months planning a one-day event in Dallas where all of the new models would be on display. It was primarily for dealers, but all in all, Deere flew nearly 6000 people in from all over the world to see these new tractors. Here’s a neat little promo video Deere’s historical team put together using footage from that day.

The full model lineup – just about everything Deere had in its product catalog – was on display the morning of August 30, 1960 in the 15-acre parking lot of the Cotton Bowl. At the time, it was over $2M in inventory! Crazy to think that two X9s on a dealer’s lot would eclipse that number by a wide margin today, huh? (BTW – Each of those letters on the dome? They’re 24′ tall!)

The one-day event was a big deal all the way around, featuring fireworks, music from Grammy-winning bands, food, and lots more. However, the one event that stood out more than anything else? That happened at the exclusive Neiman-Marcus department store in downtown Dallas. There, at the jewelry counter, stood a great big 20′ long gift-wrapped box. At noon, Tish Hewitt (CEO Bill Hewitt’s wife) cut the ribbon and opened that great big box to reveal a 3010 Diesel. Not just any 3010, though. This one was draped in dozens of carats of diamonds. People talk about bling’d-out tractors…well, in this case, Deere did it first. It was a big publicity thing, and the diamonds (held in place by scotch tape) were removed after the crowd had cleared out, but still…

I can’t even begin to imagine how much money the company spent on that event – it had to have been millions!

Did it pay off?

Absolutely.

Getting the John Deere 4010 and the rest of the New Gen tractors out the door wasn’t cheap; the new equipment and tooling required for production was well over $20M, according to the annual reports. However, Bill Hewitt’s challenge to the company – “pass International Harvester” – was one that everybody took seriously, knowing full well what it would require to do it.

By 1963, the hard work paid off. Annual reports show that Deere’s annual sales in 1963 were $762M, while Harvester’s were only $664M. They’d FINALLY done it.

It had taken longer than planned – the tractors were supposed to launch in 1958, but building from the ground up takes time. The x20 & x30-series two-cylinders? They were both moves intended to buy enough time to make certain that when the line released, they were ready. All in all, the sales were very brisk, and total production for the John Deere 4010 was betweeen 57-58,000 (I’ve seen multiple different numbers).

Wrapping it up…

I keep coming back to this, but I think it’s the absolute truth. The reason that the John Deere 4010 and the rest of the New Generation of Power were so successful is due to the utter secrecy of the project. They surprised EVERYBODY – even many of their own employees – with these tractors when they launched for the 1961 model year. Nobody saw it coming (regardless of what people may tell you – hindsight is 20/20…), and because of that, they couldn’t react fast enough to compete! It set the wheels in motion for Deere to lead the race to more modern farming, and it’s one of many reasons that they are who they are today…

…and it all started in a meat market.

Below, you’ll find the auction info one more time. Matt Maring has a terrific retirement sale in the works with this one, with four 10/20-series tractors as well as some good mid-range workhorses that’ll fit in on just about any farm today!

Auction Date: June 16, 2022 – 10AM CDT (Online bidding is open right now.)

Auctioneer: Matt Maring Auction Co.

Format: Onsite with online bidding – 10AM CDT start time on the auction!

Location: Boyd, WI

Auction Catalog

Link to the 1961 John Deere 4010

Side note: There’s lots of great books out there on Deere history. Here’s two of them that I recommend. Hit the photos for more information! In the case of Merle L. Miller’s book, I’ve also included a link to Amazon to pick it up – it’s not a real easy book to find!