A John Deere rotary engine…yep, that was a thing for a while.

Wait…what? Rotary power? I thought those were for little import cars and stuff.

You’re right…sorta.

Stick with me. We’ll get into it.

First, let’s talk about this little 2950 MFWD, since it’s marginally related to the story.

Update: This tractor sold on January 19, 2022. However, there’s plenty of John Deere 2950s out there. Check out 2950s listed on Tractor Zoom here.

Details

Bidding Opens: 1/12/22 – 5PM Central

Bidding Closes: 1/19/22 – 10AM Central

Location: Manchester, IA

Auctioneer: Old 20 Auctions

TZ Auction Listing

So here’s the thing about row-crop SoundGard tractors that don’t have a model number starting with 4; they were all built in Mannheim, Germany. They were very successful over in Europe, as their footprint was a pretty good fit for some of the smaller farming operations over there. However, they also sold pretty well here in the States. They were a pretty handy size for utility, secondary tractor-type stuff. You’ll often find them with a loader or a bale spear, too. Lots of farmers used them to move bales around or for snow removal in the winter (we had a 2555, and it always worked pretty well for that).

The Bad Rap

At any rate, these tractors often get kind of a bad rap in Deere circles. Furthermore, I’ve heard more than a few folks say stuff like, “It’s not a real Deere if it didn’t come from Waterloo or Dubuque,” and plenty of other stuff like that. If you’re in that camp, I’m sorry to burst your bubble…but you’re wrong. Just because the model number doesn’t start with a 4 doesn’t make it a flaming pile. It’s all about perspective. Heck, up until about the time I graduated from college and moved out to Iowa, our 2555 was the workhorse! It was a pretty darn good tractor for us! (There again, though…we bought it because it fit the purpose. We didn’t need big tractors!)

Some like to claim that they’re not well-built, and prone to all manner of failures. They say that they’ll nickel and dime you to death. But as with most tractors, a lot of it comes down to who owned the tractor, and how well they took care of it. (I know that a few of the Mannheim tractors are prone to premature hydraulic failure, but for some reason I think that was more of a 40-series problem.)

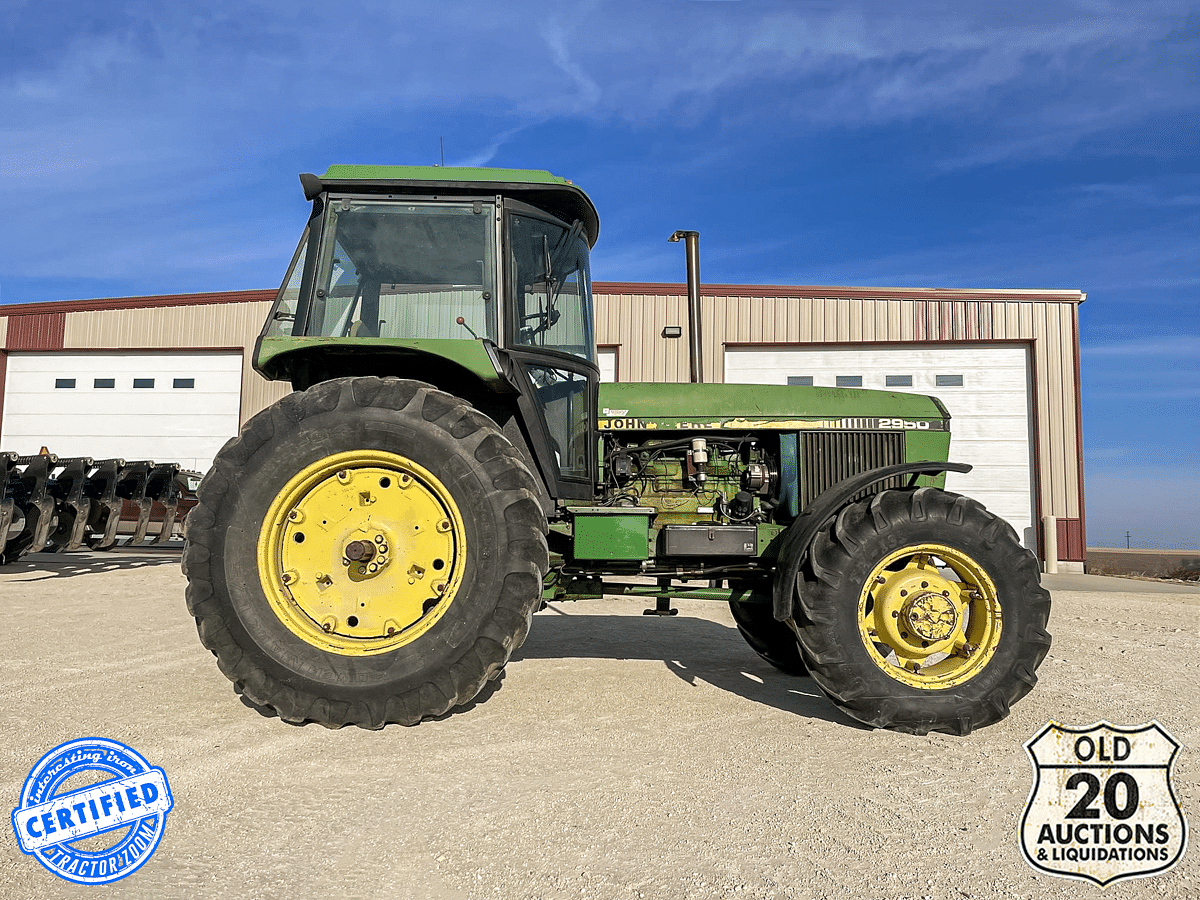

The 2950 that sold in 2022…

This particular 2950 is 39 years old, and has lived 37 of ’em at the same farm in Lamont, IA! While it’s not technically a one-owner tractor, it may as well be. The consignor used it primarily for dragging a feed wagon for his cattle. It may not look like much, but from what the auctioneer tells us, it’s been quite well-maintained for the most part. Always got service and maintenance on schedule, for the most part (the A/C lines need to be replaced – I don’t know if that’s a recent issue or if it’s been broken for a while). The rubber’s good, it starts up, runs and drives fine, and the MFWD works well, too. Really and truly, I think this tractor likely just needs a good, thorough cleaning and some interior work.

What’ll it bring?

I think $14-15K probably brings this one home. It’s not perfect, but it’s also not a basketcase. It’s been well maintained according to the auctioneer, but at over 12,000 hours, it could potentially be ready for an overhaul. That could scare buyers away. However, parts are pretty easy to find for these tractors and they’re not tremendously difficult to work on. I’ve been wrong plenty of times before, but I feel reasonably confident in a $14-15K estimate. We’ll find out in a few weeks!

Ryan’s Estimate: $14-15K

Actual Sale Price: $18,100

If the 2950 isn’t what you’re looking for, browse over 2700 other John Deere tractors on Tractor Zoom!

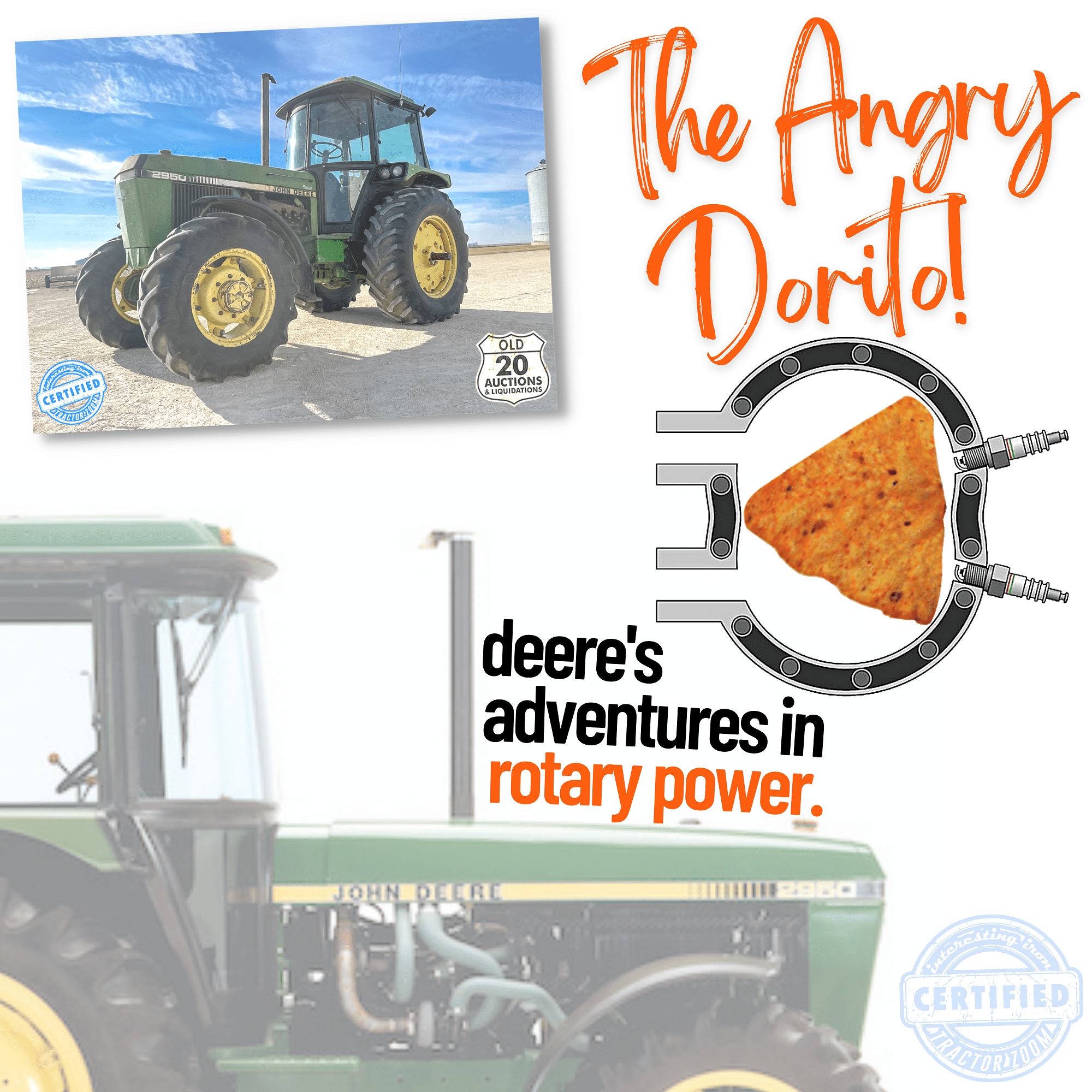

Deere & The Angry Dorito

Okay Interesting Iron guy…what’s up with this angry Dorito thing? Quit stalling! *drums fingers impatiently*

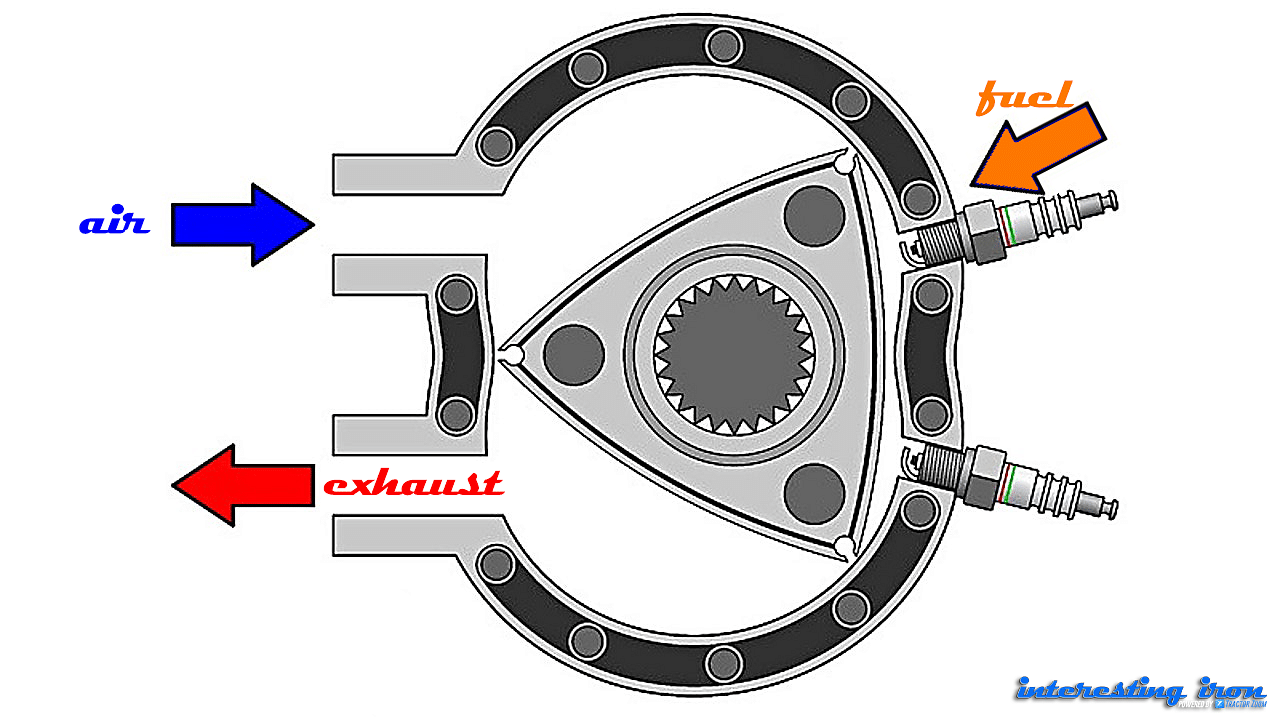

When we think of engines, we all think of the typical design. Inline six, V8, four-banger…whatever. We all think of a more or less conventional push-rod design. Air & fuel go in, pistons go up and down, air & fuel explodes, various things rotate, rinse and repeat. Right? That’s the super-simple version of a very complex process with at least 40 moving parts. All of those moving parts need to move in the right direction at the right time. If they don’t, engines make bad noises, four letter words are yelled, and the day pretty much comes to a grinding halt.

But what if there was another engine option? One that still burned flammable fuels, but only had two moving parts?

There is. It’s called the Wankel Rotary Engine, and it’s what the John Deere rotary engine was based on.

Here’s what it looks like in cross-section.

The engine was dreamed up (literally – he claimed to have seen it in a dream) by Felix Wankel when he was just a teenager in Germany. It took him some time to get it to work, and his progress was hampered by WWII (French soldiers destroyed his shop), but eventually he got it to work in 1957. At the time he was working for a German company called NSU. The engine was licensed a year later to Curtiss-Wright (an aircraft engine company), and after that, auto manufacturers basically lined up to do the same. Over the next twenty years, the Wankel design was used in a handful of different applications, ranging from cars to generators to military application. Some were successful, some weren’t. (More on that in a bit.)

Skip forward a couple decades…

In 1983, Deere bought patent rights from Curtiss-Wright, because they wanted to experiment with Wankel’s design and see if they could improve it and find a way to use it in military applications for the government. The purchase put the company in the driver’s seat for US-based production, and furthermore, the package came with pre-existing experimental stuff that they could improve upon right out of the gate. Furthermore, since they already plenty of manufacturing facilities in place, when the time was right, they’d be ready to tool up for production.

Thus, the John Deere Rotary Engine Division was born. They called it REDIV for short.

The prototypes of the John Deere rotary engine was very cool, because it coupled Deere’s two-cylinder past with the future. The major enhancement they added was the ability to burn a bunch of different types of fuel in the same engine; diesel, kerosene, gasoline, jet fuel – even natural gas! They called it SCORE – Stratified Charge Omnivorous Rotary Engine. The engine used two injectors to deliver fuel in series coupled with the spark to ignite it (even when burning diesel fuel). That was the Stratified Charge part of the acronym. Omnivorous referred to the ability to burn multiple fuels, and the Rotary Engine part was self-explanatory.

SCORE 580

Deere built a handful of different prototype sizes, but the SCORE 580 was the most successful. It was a two-rotor design that stacked two 5.8L rotors together in series running the same shaft. It made BIG power, too. Wankel engines are very smooth in operation, and those rotors will spin up really quickly. Even though they were considered low-RPM engines (3600 RPM in testing, I believe), the early prototypes made in excess of 500 horse on the dyno! Furthermore, they were very compact, and since they didn’t have giant pistons and a crankshaft, they weighed next to nothing!

So if you’re John Deere, and you’ve got a new prototype engine, what do you do with it? Shove it in a tractor, of course – even if it’s not really meant for one! They chose a Mannheim-built 2950 MFWD to drop one of them in. The tractor you see below has a 1.3L 2-rotor design that made just about 100 horsepower. As you can see, it’s a fair bit smaller than the 5.9L inline six that was normally shoehorned in the engine compartment!

The end goal was to sell these to the government for use in tanks and armed personnel carriers for the battlefield, but from what I gather, Deere also wanted to find things to do with these motors for consumer products. They built multiple different prototypes ranging from a 0.7L single-rotor (rated for 80 horse) up to a six-rotor design that was capable of well over 2200 horse!

So why didn’t these things take off?

There’s a handful of reasons. While the Wankel design was very simple and held a lot of benefits over piston powered engines, it wasn’t perfect.

- They weren’t very efficient. The Wankel was a pretty low-compression design. If the combustion chamber didn’t burn completely, the rotor would push unburnt fuel out the exhaust port. As such, it took more fuel (i.e., more costly), and if it didn’t burn clean, it left carbon deposits on the sidewalls of the chamber.

- They were capable of making tons of power and torque, but it all came at the top end of the tachometer – which is NOT where tractors and heavy tanks need it. (Imagine trying to pull a fully loaded grain cart with a tractor that only made torque at 5000 RPMs. You’d have to rev the motor to the moon, try not to dump the clutch, and pray that the transmission held together. That’s probably an exaggerated example, but you get my point.)

- Engines that run at high RPMs end up burning oil. Not good for emissions (which were starting to become a big deal at the time), and furthermore, if the oiling couldn’t keep up (or the oil started to break down), the rotating assemblies got real hot. Like, weld-themselves-together hot. Deere never could find a fix for that.

By the spring of 1991, the John Deere Rotary Engine Division engineers concluded that their take on the Wankel design just wasn’t going to work. It wasn’t for lack of effort, though; for those 8 years, I’m told that REDIV was the place to work if you were an engineer. Deere gathered some of the best and brightest to work on the project alongside the Curtiss-Wright engineers who came with the deal. One of my friends works at Deere today, and several of her coworkers were involved in the project. They said that you could almost feel the energy when you walked in the door. They were genuinely pumped up to go to work every day. It was a brand new technology, and it was exciting to be part of it!

What happened to the 2950 and prototype SCORE 580s?

As I understand it, the tractor was scrapped. I don’t believe that it exists today.

In 1991, the company sold the John Deere Rotary Engine Division and most all of its assets to a company called Rotary Power International, Inc. I believe a total of 80 employees went with it and continued searching for solutions that would make the design work. Unfortunately, the company went under about 20 years ago. There were only eight employees left when they folded, from what I understand.

As far as the engines go, most of them were destroyed. A few were saved for display purposes. There was, however, one fully functional two-rotor engine that didn’t get destroyed. It was set up to run on natural gas more or less as a generator. It was sold in 1999 and ended up in what appears to be a private collection in Calgary. Apparently, the team at RPI had continued to turn up the wick on that one, because it dyno’d at over 1200 horse! Check it out!

I tried like heck to find some video of this thing running, but I don’t think it’s out there. (If I do find a video, I’ll update this post!)

Uh…angry Dorito? Still waiting, Interesting Iron guy!

Oh yeah, that.

Remember I told you that these motors are really smooth, they rev really fast, and they make all their power at high RPM? Well, when they’re built for racing, they make the most angry noises EVER.

All from Dorito-shaped rotors. Hence the term, “The Angry Dorito”… (I guess for the John Deere rotary engine, it would be multiple angry Doritos, and they’d be giant.)

Watch the first 45 seconds of this video and you’ll see what I mean (and this is nowhere near the redline for this build).

Wankels haven’t been entirely unsuccessful. Of all the auto manufacturers who licensed the design over the years, Mazda has had the most success. They used it in at least a half-dozen different cars (and a pickup truck, I think), but the one that carved this engine’s place in history was the RX-7. They launched it in 1979 and it was pretty much an immediate hit. Because the car was so lightweight, the lack of low-RPM torque wasn’t much of an issue. Over several generations, they created one of most-recognized sportscars on the planet. By the time Mazda pulled the plug in 2002, the RX-7’s tiny motor (a whopping 1.3L of displacement) made about 280 horsepower!

But it wasn’t just the RX-7 that succeeded. In 1991, Mazda became the first Japanese automaker to win the 24 hours of Le Mans – possibly the most demanding race in the world – using a 4-rotor engine in their 787B race car.

Final thoughts…

Rotary engines have their place…just not in tractors, tanks, or armored personnel carriers. I doubt we’ll ever see another John Deere rotary engine again; as we saw just this week, their future goals are definitely moving towards autonomous farming and lowering emissions. The Wankel design isn’t much good at either of those things.

It makes a heck of a race car engine, though!

I’m out for next week, but I know that the week after, I’ll have a good one. Stay warm, and if you’re indoors, why not browse tractors on Tractor Zoom?

Also, while I’m thinking of it, I need to pass along a thank-you to Lee Klancher and the team at Octane Press for the use of the photo of that prototype 2950 with the rotary motor in it. That photo appeared as part of a very cool little sidebar article about REDIV in John Deere Evolution, the brand new (and finally in stock) book about the history of John Deere! (I was honored to have been one of the co-authors of that book, too!) 350-some odd pages of all of the things that made Deere who they are today!

Check out John Deere Evolution in more detail!